Braided wire has proven highly effective in shielding electronic equipment and devices from radio frequency interference (RFI) and electromagnetic interference (EMI) and improving signal fidelity. For this reason, it is preferred in various critical applications, such as those found in the automotive, aerospace, and medical industries.

International Wire is one of the largest copper and copper-alloy conductor and braided wire producers in the US, with extensive wire manufacturing experience. We can deliver various braided wire configurations to meet your unique needs and application requirements.

Braided Wire Explained

The primary purpose of braided wire is to shield electronic and telecommunications devices from EMI and RFI. This is important because interference can cause excessive signal noise and incomplete data transmission between critical equipment. In addition to EMI/RFI shielding, braided wires are also suitable for grounding applications, flexible connections, and providing mechanical protection for cables.

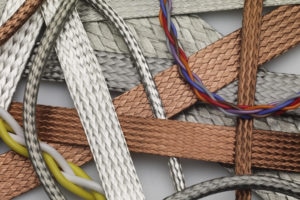

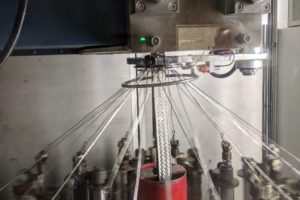

Braided wire can be made with different numbers of wires depending on the application and diameter required. Two common configurations are:

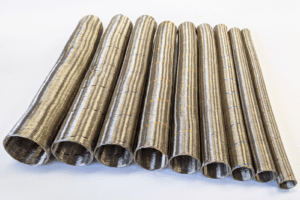

- Tubular braid. Braided wires enclose the core in a circular cross-section. This round shape is useful for fitting cables into confined or tight spaces inside or around equipment or machinery. Tubular braided wires can be constructed from various wire materials, including tinned copper, nickel or silver-plated copper, bare copper, and stainless steel.

- Flat braid. Flat braided wire is made by flattening tubular braids with a pressure roller. This makes the cable more flexible and increases its surface area. A flat braid also has lower electrical resistance, which makes it a common choice for grounding and lightning protection.

Advantages of Braided Wire

Compared to solid or stranded wire alternatives, braided wire offers many important benefits:

- Flexibility. The crossed and woven pattern of the braided wires allows them to shift and adjust without compromising protection when the cable is bent. This also allows them to more easily wrap around corners or fit into small electrical or other enclosures.

- Durability. The individual wires are closely spaced to enclose the core and provide a protective layer of metal. This reduces abrasion and wear in applications that are exposed to harsh operating conditions.

- Lower electrical resistance. Braiding creates a larger cross-section of wire or, when flattened, a wider wire. This increased surface area lowers electrical resistance. Using materials that are naturally less resistant, like copper and aluminum, also helps keep resistance low. As resistance decreases, conductivity increases so the flow of electrical current is not impeded. This means less heat is generated, and operation is more energy efficient.

- EMI shielding. Braided wire reduces EMI interference by acting as a shield, preventing external electrical noise from affecting the wire’s signal transmission. This is crucial for industries such as medical and telecommunications where signal clarity is paramount.