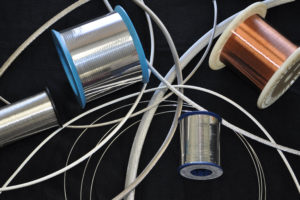

The choice of wire materials in manufacturing and industrial applications influences the efficiency and reliability of the product or system. International Wire Group, a leader in the wire manufacturing industry, offers a range of wire materials tailored to meet the needs of various applications. Let’s examine the different types of wire materials, exploring their unique properties, advantages, and applications.

What Are the Main Types of Wire Materials?

International Wire Group provides an extensive range of wire materials, each tailored for specific applications. Here is an overview of the common wire materials we carry:

- Bare copper wire: Valued for its superb conductivity and flexibility, bare copper wire serves as the backbone of many electrical systems.

- Tin-plated copper wire: For environments where corrosion is a concern, tin-plated copper wire offers enhanced resistance and solderability, extending the lifespan of electrical cables.

- Nickel-plated copper wire: Nickel-plated copper wire has enhanced heat resistance and strength, making it indispensable for applications that operate under high temperatures up to 260 C.

- Silver-plated copper wire: With its exceptional conductivity, silver-plated copper wire is the go-to for applications requiring high signal quality, such as data transmission and high-frequency applications.

- Aluminum wire: For those seeking a balance between cost and performance, aluminum wire is a lightweight, less expensive alternative to copper wire and is often used in power transmission.

- Bronze wire: Bronze wire’s corrosion resistance and strength make it ideal for challenging environments.

- Stainless steel wire: Known for its superior resistance to both corrosion and heat, stainless steel wire thrives in harsh industrial applications.

- Copper alloy wire: These wires merge the best traits of multiple metals to meet specialized requirements, from increased strength to improved conductivity.

Advantages of Each Wire Material

International Wire Group’s diverse portfolio of wire materials ensures a solution for every project. At a glance, these are the main advantages of each wire material:

- Bare copper wire: These wires are highly useful for their exceptional conductivity, durability, malleability, and solderability. Bare copper wire also offers good creep resistance and a high melting point.

- Tin-plated copper wire: This type of wire has superior corrosion resistance in moist or salty conditions and is easy to solder.

- Nickel-plated copper wire: This corrosion-resistant wire enhances electrical performance and bendability, ideal for demanding electrical environments.

- Silver-plated copper wire: When plated with silver, this copper wire provides outstanding electrical and thermal conductivity.

- Aluminum wire: With its notable creep resistance, corrosion resistance, armoring properties, and self-weight-bearing capabilities, aluminum wire is ideal for wiring large buildings.

- Bronze wire: Bronze wire provides more durability and strength than bare copper wire, and it also outperforms most steels in heat and electricity conduction.

- Stainless steel wire: Stainless steel wire is an aesthetically appealing wire that offers high strength, corrosion resistance, low maintenance, and biocompatibility.

- Copper alloy wire: These wires are precision-engineered to enhance strength and reduce weight in weight-sensitive applications.

By matching a wire material’s distinct benefits to your needs, you can optimize the wire’s performance and longevity in its intended application.