International Wire Cable Services is a premier supplier of bus bar wires, braids, grounding wires, and other wire solutions. Our broad Wire and Cable industry experience, combined with our extensive wire manufacturing capabilities, enables us to deliver quick and quality solutions for a wide range of industries and applications. Whether our customers require bare copper wire, tinned copper wire, tinned copper braids, or stainless steel braids by the foot or by the pound, we can meet their wire needs. Our dedicated team members—including engineering support and customer service experts—are committed to providing customers with the best possible experience and solutions, whether they have standard or highly specialized requests.

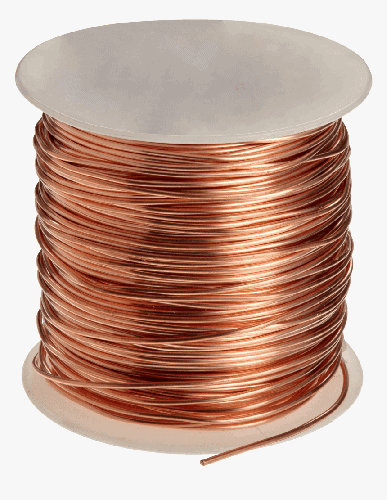

Bare Copper Wire

Solid Bare copper wire—also often referred to as single end ground wire—is one strand of wire, uninsulated, and unshielded, drawn to gauge from a single solid copper rod. Bare Copper has excellent conductive properties. Additionally, it has the flexibility to be bent or twisted while maintaining its strength and durability.

Bare Copper Wire at International Wire Cable Services

At International Wire Cable Services, we offer solid soft-drawn and annealed bare copper wire.. Bare single end wire is available in sizes ranging from 6 to 28 AWG and other sizes upon request. Solid bare copper wire complies with the standard specification outlined by ASTM B-3.

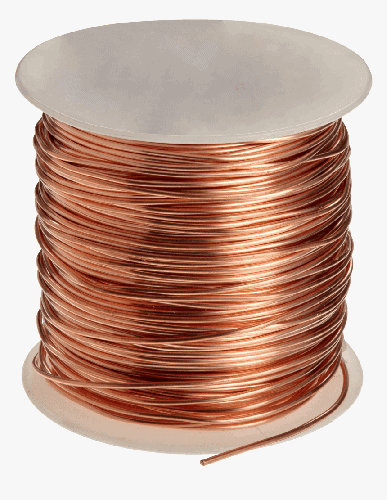

Bare Copper Wire

Solid Bare copper wire—also often referred to as single end ground wire—is one strand of wire, uninsulated, and unshielded, drawn to gauge from a single solid copper rod. Bare Copper has excellent conductive properties. Additionally, it has the flexibility to be bent or twisted while maintaining its strength and durability.

-

Applications of Bare Copper Wire

Bare copper wire is widely used in commercial, industrial, and residential grounding applications. Bare wire is often utilized as a conductor in building wire and telecommunications cables. Solid bare wire can be drawn to smaller sizes and used for the fabrication of stranded conductors. Applications include electrical devices and systems that require high electrical conductivity, including:

- Overhead electrical systems: These systems use uninsulated wires and cables to transmit electricity across long distances.

- Components in large cables: These cables consist of multiple conductors.

Bare Copper Wire at International Wire Cable Services

At International Wire Cable Services, we offer solid soft-drawn and annealed bare copper wire.. Bare single end wire is available in sizes ranging from 6 to 28 AWG and other sizes upon request. Solid bare copper wire complies with the standard specification outlined by ASTM B-3.

Tinned Copper Wire

Tinned copper wire—also known as tin-dipped or tin-plated copper wire—refers to uninsulated copper wire coated with a thin layer of tin. Tinned Copper Wire, as well as Bare copper Wire, has excellent electrical conductivity and solderability, while the tin layer protects it from corrosion and oxidation. These properties make tinned copper wire a better choice than bare copper wire for wet, humid, and high-temperature environments.

Tinned Copper Wire at International Wire Cable Services

At International Wire Cable Services, we offer solid soft-drawn tinned copper wire. Tinned single end wire is available in sizes ranging from 6 to 28 AWG and other sized upon request Solid tinned copper wire complies with the standard specification outlined by ASTM B-33. Other typical applications include: electrical cables, heaters high-temperature instruments, industrial machinery.

Tinned Copper Wire

Tinned copper wire—also known as tin-dipped or tin-plated copper wire—refers to uninsulated copper wire coated with a thin layer of tin. Tinned Copper Wire, as well as Bare copper Wire, has excellent electrical conductivity and solderability, while the tin layer protects it from corrosion and oxidation. These properties make tinned copper wire a better choice than bare copper wire for wet, humid, and high-temperature environments.

-

Applications of Tinned Copper Wire

Tinned copper wire finds use in numerous industrial applications. For example:

- It is used in moisture-rich applications (e.g., marine equipment, subway systems, wastewater treatment facilities) since its enhanced corrosion resistance allows it to tolerate constant exposure to water and saltwater without failure.

- It is used as bus bar wire, which distributes power from the centralized bus bar to outlying equipment.

- It is used in ground electrical systems since its tin coating protects it against corrosion caused by certain types of soils.

Tinned Copper Wire at International Wire Cable Services

At International Wire Cable Services, we offer solid soft-drawn tinned copper wire. Tinned single end wire is available in sizes ranging from 6 to 28 AWG and other sized upon request Solid tinned copper wire complies with the standard specification outlined by ASTM B-33. Other typical applications include: electrical cables, heaters high-temperature instruments, industrial machinery.

Tinned Copper Tubular Braids

Tinned copper tubular braid has a round configuration, it is braided with a specific number of ends (wires) to the specified nominal inside diameter (ID). Tinned Copper Tubular Braids provide good conductivity, resistance to corrosion, and are easy to solder.

Tinned Copper Tubular Braids at International Wire Cable Services

At International Wire Cable Services, our tinned copper tubular braids are available in a variety of constructions made with 30 AWG and 36 AWG wire. Individual ends comply with the standard specification outlined by ASTM B-33.

Tinned Copper Tubular Braids

Tinned copper tubular braid has a round configuration, it is braided with a specific number of ends (wires) to the specified nominal inside diameter (ID). Tinned Copper Tubular Braids provide good conductivity, resistance to corrosion, and are easy to solder.

-

Applications of Tinned Copper Tubular Braids

Tinned copper tubular braids have become an industry standard for many applications. They are traditionally used in most industrial applications like automation, manufacturing, and renewable energy.

Tubular braids create lightweight, flexible construction. They are commonly used for the protection of cables against abrasion, corrosion, and mechanical damage. Other applications include shielding cables from electromagnetic, electrostatic, and RF interference.

Tinned Copper Tubular Braids at International Wire Cable Services

At International Wire Cable Services, our tinned copper tubular braids are available in a variety of constructions made with 30 AWG and 36 AWG wire. Individual ends comply with the standard specification outlined by ASTM B-33.

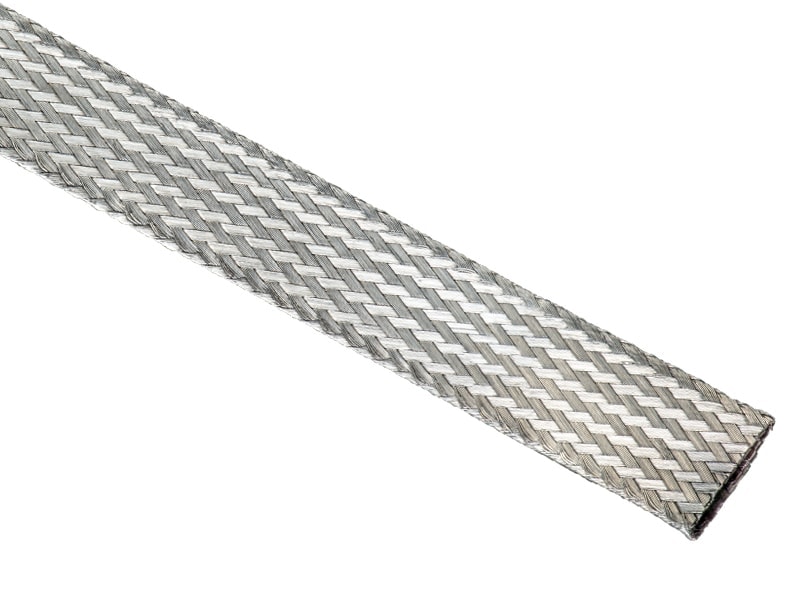

Tinned Copper Flat Braids

Tinned copper flat braid is braided with a certain number of ends (wires) to the specified width and thickness, initially it has round configuration, then it is flattened by a pressure roller. Flat Braids create a flexible construction and come in assortment of materials, like bare copper, tinned copper, stainless steel, silver-plated copper, nickel-plated copper. Tinned Copper Flat Braids provide good conductivity, resistance to corrosion, and are easy to solder.

Tinned Copper Flat Braids at International Wire Cable Services

At International Wire Cable Services, our tinned copper flat braids are available in a variety of constructions made with 30 AWG and 36 AWG wire. Individual ends comply with the standard specification outlined by ASTM B-33.

Tinned Copper Flat Braids

Tinned copper flat braid is braided with a certain number of ends (wires) to the specified width and thickness, initially it has round configuration, then it is flattened by a pressure roller. Flat Braids create a flexible construction and come in assortment of materials, like bare copper, tinned copper, stainless steel, silver-plated copper, nickel-plated copper. Tinned Copper Flat Braids provide good conductivity, resistance to corrosion, and are easy to solder.

-

Applications of Tinned Copper Flat Braids

Tinned copper flat braids (also known as ground straps and earthing braids) are commonly used for earth/ground connections to protect individuals and equipment by serving as that safe path to grounding a live current. Other common applications include:

- Flexible connections

- Electrical leads

- Connections for lightning protection systems

- Electrical bonding

Tinned Copper Flat Braids at International Wire Cable Services

Tinned Copper Flat Braids at International Wire Cable Services

At International Wire Cable Services, our tinned copper flat braids are available in a variety of constructions made with 30 AWG and 36 AWG wire. Individual ends comply with the standard specification outlined by ASTM B-33.

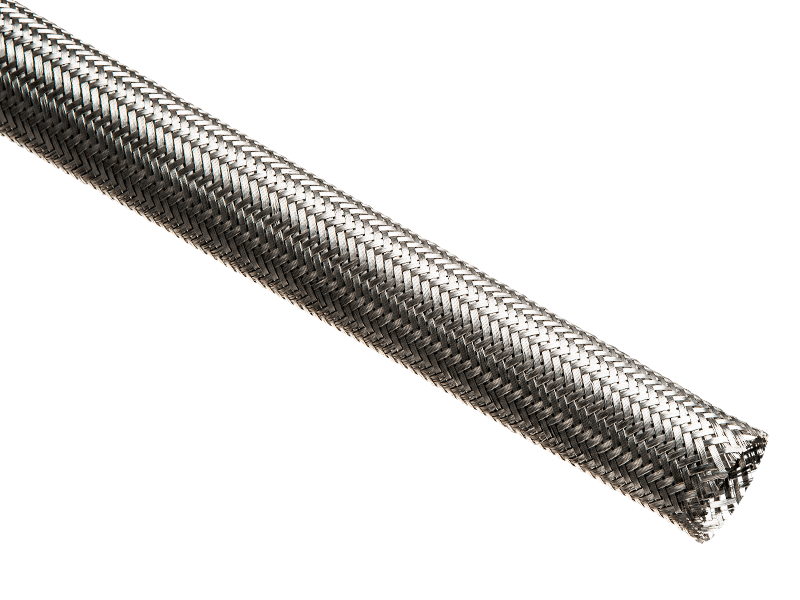

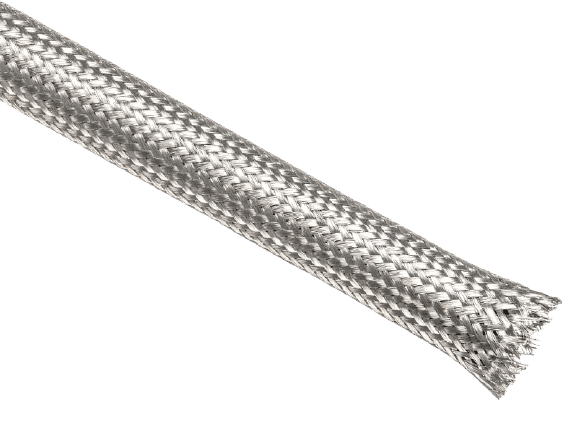

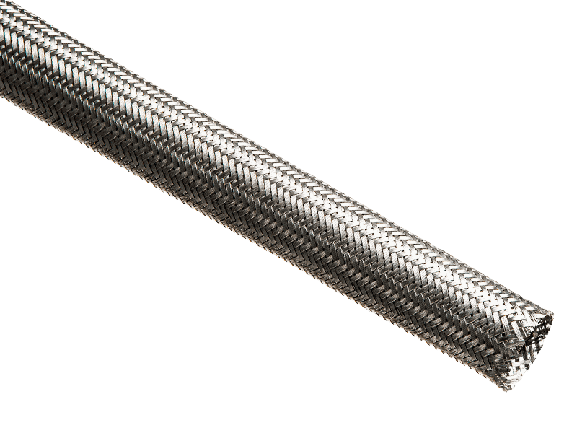

Stainless Steel Tubular Braids

The process of manufacturing stainless steel tubular braids is the same as tinned copper tubular braids. Stainless Steel Tubular Braids provide good performance at extreme temperature, they are durable and flexible. Similar to other tubular braids, stainless steel tubular braids are commonly used in cabling applications, where they provide protection against mechanical damage and electromagnetic interference. They are well-suited for use in abrasive, corrosion, high-temperature, and outdoor environments due to the stainless steel properties (e.g., resistance to abrasion, chemicals, high-temperature, and ultraviolet radiation resistance).

Stainless Steel Tubular Braids at International Wire Cable Services

At International Wire Cable Services, our stainless steel tubular braids are available in a variety of constructions made with 30 AWG and 36 AWG wire. We offer braids made with Type 304 (non-magnetic) stainless steel online, but we can also accommodate requests for braids made with Type 430 (magnetic), Type 316, and Type 321 stainless steel if needed.

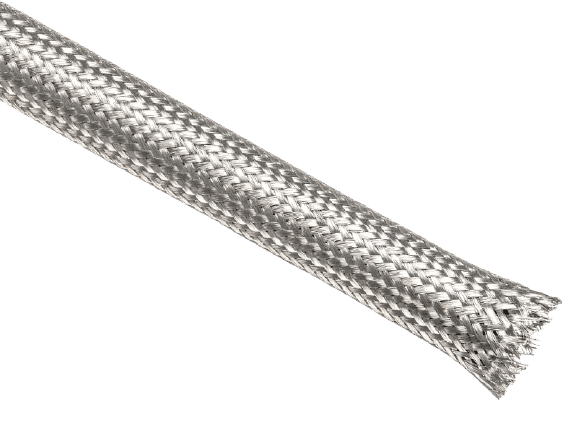

Stainless Steel Tubular Braids

The process of manufacturing stainless steel tubular braids is the same as tinned copper tubular braids. Stainless Steel Tubular Braids provide good performance at extreme temperature, they are durable and flexible. Similar to other tubular braids, stainless steel tubular braids are commonly used in cabling applications, where they provide protection against mechanical damage and electromagnetic interference. They are well-suited for use in abrasive, corrosion, high-temperature, and outdoor environments due to the stainless steel properties (e.g., resistance to abrasion, chemicals, high-temperature, and ultraviolet radiation resistance).

-

Applications of Stainless Steel Tubular Braids

Common applications include:

- Expansion joints: The flexibility and durability of stainless steel tubular braids make them perfect for use in applications where continuous and repetitive movement is expected.

- Outdoor wiring: Since stainless steel tubular braids are resistant to extreme temperatures and UV radiation, they are ideal for a range of outdoor wiring applications.

- Sleeving: Stainless steel tubular braids are suitable for sleeving in automobiles since they have an extremely high melting point.

Stainless Steel Tubular Braids at International Wire Cable Services

At International Wire Cable Services, our stainless steel tubular braids are available in a variety of constructions made with 30 AWG and 36 AWG wire. We offer braids made with Type 304 (non-magnetic) stainless steel online, but we can also accommodate requests for braids made with Type 430 (magnetic), Type 316, and Type 321 stainless steel if needed.

We supply our wire products to a number of respected manufacturers worldwide, including:

Quality Wire Solutions From International Wire Cable Services

From bare and tinned solid copper wire to braids made of tinned copper and stainless steel International Wire Cable Services offer a broad product selection that can meet the needs of nearly any application. Our wire solutions are used to support everything from complex electronics and data communication devices to home appliances and power tools. By following an advanced quality assurance process, we ensure each product we manufacture is thoroughly inspected and tested according to the strictest industry standards, so customers know they can rely on them to meet their most demanding requirements.

We also offer various special services, including:

- Cutting wire to length

- Re-spooling

- Bobbin winding

- Custom labeling

- Wire twisting

- Cable and harness over braiding and shielding

- Engineering and technical support

- Stocking program