The Advantages of Using Laminated Flexible Busbars in Automotive Design

Laminated flexible busbars are electrical conductors that are designed to provide a compact, flexible, and highly efficient solution for power distribution. They play a critical role in various power applications. Here, we will dive into the various benefits of laminated flexible busbars and explain how they are used in the automotive industry.

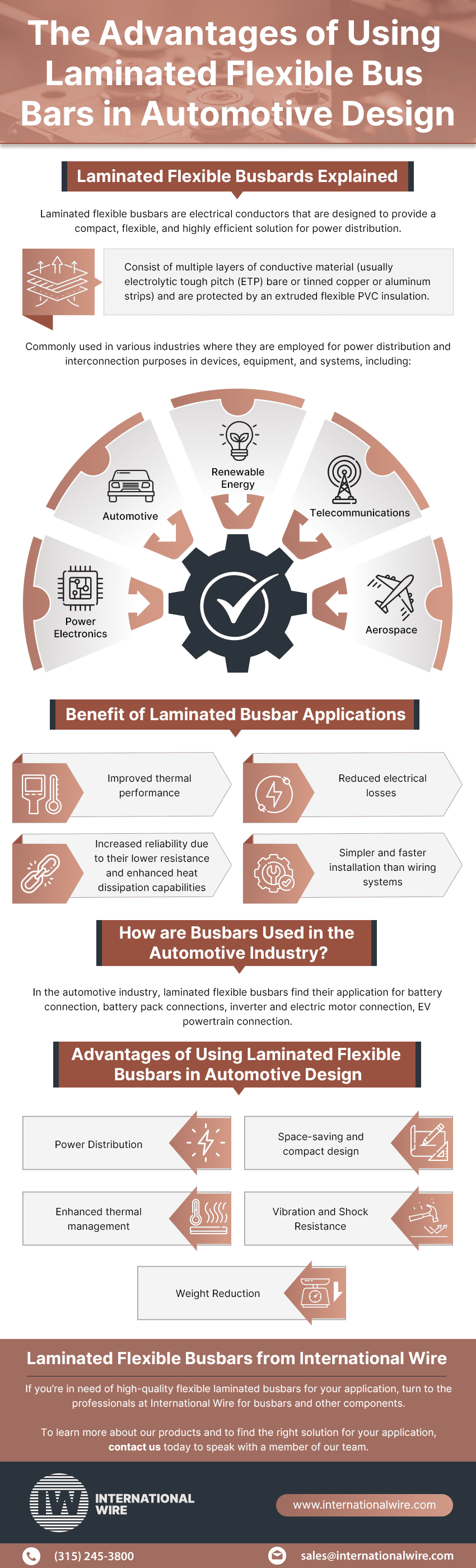

Laminated Flexible Busbars Explained

EVs often rely on busbars to conduct the battery’s high-voltage power to the vehicle’s E-powertrain. International Wire designs busbars to customers’ specifications, accounting for operational needs, current-carrying capacity, temperature requirements, and insulated bar dimensions.

Laminated busbars consist of multiple layers of conductive material (usually electrolytic tough pitch (ETP) bare or tinned copper or aluminum strips) and are protected by an extruded flexible PVC insulation.

The construction of flexible laminated busbars allows for a reduction in size and weight compared to traditional rigid busbar systems. The flexible nature of the busbars enables them to be easily bent, twisted, or shaped to fit into tight spaces or conform to complex geometries, making them suitable for applications with limited space or irregular layouts.

Flexible busbars are commonly used in various industries, including power electronics, automotive, renewable energy, telecommunications, and aerospace, where they are employed for power distribution and interconnection purposes in devices, equipment, and systems.

Benefits of laminated busbar applications

Flexible laminated busbars offer several advantages, including improved thermal performance, reduced electrical losses, and increased reliability due to their lower resistance and enhanced heat dissipation capabilities.

Flexible busbar assembly successfully and cost-effectively replaces systems consisting of cables, supporting components and connections. It is simpler and quicker to install than wiring systems.

How Are Busbars Used in the Automotive Industry?

In the automotive industry, laminated flexible busbars find their application for battery connection, battery pack connections, inverter and electric motor connection, EV powertrain connection.

Advantages of Using Laminated Flexible Busbars in Automotive Design

The following are some of the specific advantages that explain why these components are integral in automotive design:

- Power Distribution. Flexible busbars enable the distribution of high currents and voltages from the battery pack to various components and subsystems within the EV. They ensure the efficient transfer of electrical energy from the source to motors, inverters, chargers, and other power-hungry components.

- Space-saving and compact design. Laminated flexible busbars are highly flexible and custom-designed to fit into tight spaces and irregular shapes within the vehicle. This compact design allows for optimized space utilization, which is particularly crucial in the limited space of modern vehicles where every square inch matters.

- Enhanced thermal management. Automotive systems generate a significant amount of heat, especially in electric and hybrid vehicles. Laminated flexible busbars can be engineered with materials that have high thermal conductivity, such as copper or aluminum, to efficiently dissipate heat from power electronics components, batteries, and other high-temperature areas. This helps to maintain optimal operating temperatures, prolong component lifespan, and prevent thermal failures.

- Vibration and Shock Resistance. Electric vehicles are subject to constant vibration and mechanical stress due to road conditions. Flexible busbars, being more resilient and resistant to vibration and shocks compared to rigid cables, provide enhanced durability and reliability. They can withstand these harsh conditions without compromising the electrical connections.

- Weight Reduction. The lightweight nature of flexible busbars contributes to overall weight reduction in EVs. This is particularly important for electric vehicles, as reducing weight improves energy efficiency, extends battery life, and enhances the overall performance and range of the vehicle.

Laminated Flexible Busbars from International Wire

If you’re in need of high-quality flexible laminated busbars for your application, turn to the professionals at International Wire for busbars and other components.

To learn more about our products and to find the right solution for your application, contact us today to speak with a member of our team.