International Wire provides standard and custom wire products for a broad range of applications. Our wire products include copper single-end wire, stranded wire, braided wire, copper wire on bobbins, and flat wire.

Our Mission and Vision

Our Mission

Our mission is to provide quality, value-oriented, copper-based products and services that exceed our Customers’ expectations. We believe in the safety for our most valuable asset, our people. By inspiring their talent, passion and commitment we will achieve our challenging goals. We are committed to continuous improvement, environmental responsibility and a positive impact for all of our stakeholders.

Core Values

Safety

Safety

People

People

Customers

Customers

Products & Services

Products & Services

Integrity

Integrity

Continuous Improvement

Continuous Improvement

The safety of our employees is at the core of everything we do.

The people are the resource of our success. We treat one another with respect, promote teamwork, and encourage personal freedom and growth. Leadership and excellence in performance are sought and rewarded.

The customers are the reason we exist. It is through our talent, passion and commitment that we strive to exceed their expectations.

Our products & services reflect dedication to quality, innovation and value.

Our conduct demonstrates integrity and commitment to ethics, safety, health and the environment.

As an Organization we continually strive to improve our performance.

Our History

Headquartered in Camden, New York, International Wire serves customers across the United States and Europe with premium wire products. Since our founding in 1885, we have continuously grown our capabilities and expanded our operations through strategic acquisitions.

Services We Offer

-

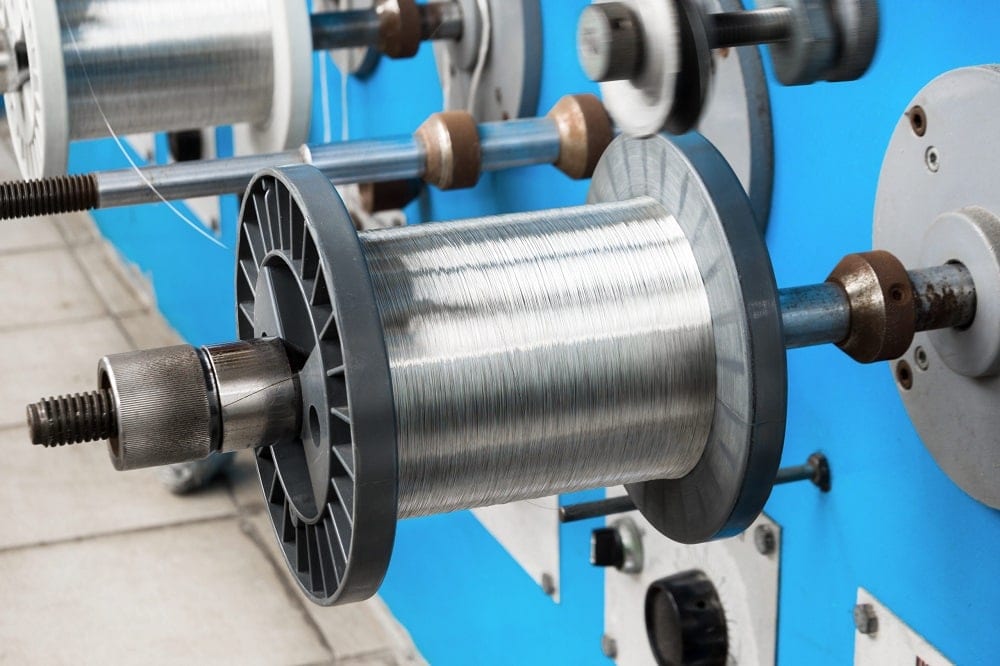

Drawing

The drawing process in wire manufacturing is a precise and critical operation that reduces the diameter of a copper rod to a finer gauge, while maintaining the material’s mechanical properties and surface finish. The drawing process is also the first process in cable manufacturing.

-

Stranding

Stranding combines multiple individual wire strands to create a single, flexible conductor. This process enhances the wire’s durability and flexibility, making it suitable for dynamic applications such as power transmission, electronics, and automotive systems. Stranded wire is also less prone to fatigue compared to solid wire.

-

Bunching

Wire bunching is the process of twisting together multiple single wire strands to form a flexible, compact conductor known as a bunched wire. Unlike stranded wire, where strands are precisely layered in a geometric pattern, bunched wire strands are randomly twisted, offering enhanced flexibility and ease of use in applications where movement, bending, or vibration is common. It is widely used in the manufacturing of cables for automotive, electronics, and consumer goods.

-

Bobbin Winding

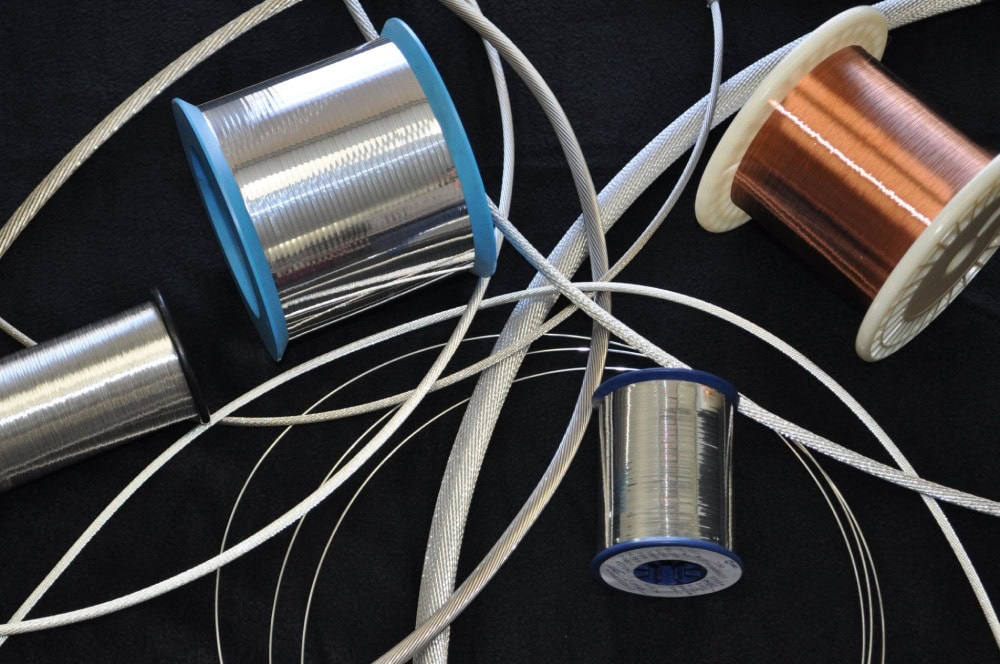

Wire is wound onto bobbins for easy handling, storage, and transportation. Bobbin winding supports production efficiency by delivering wire products in a ready-to-use format to our customers, who have their own braiding machines.

-

Braiding

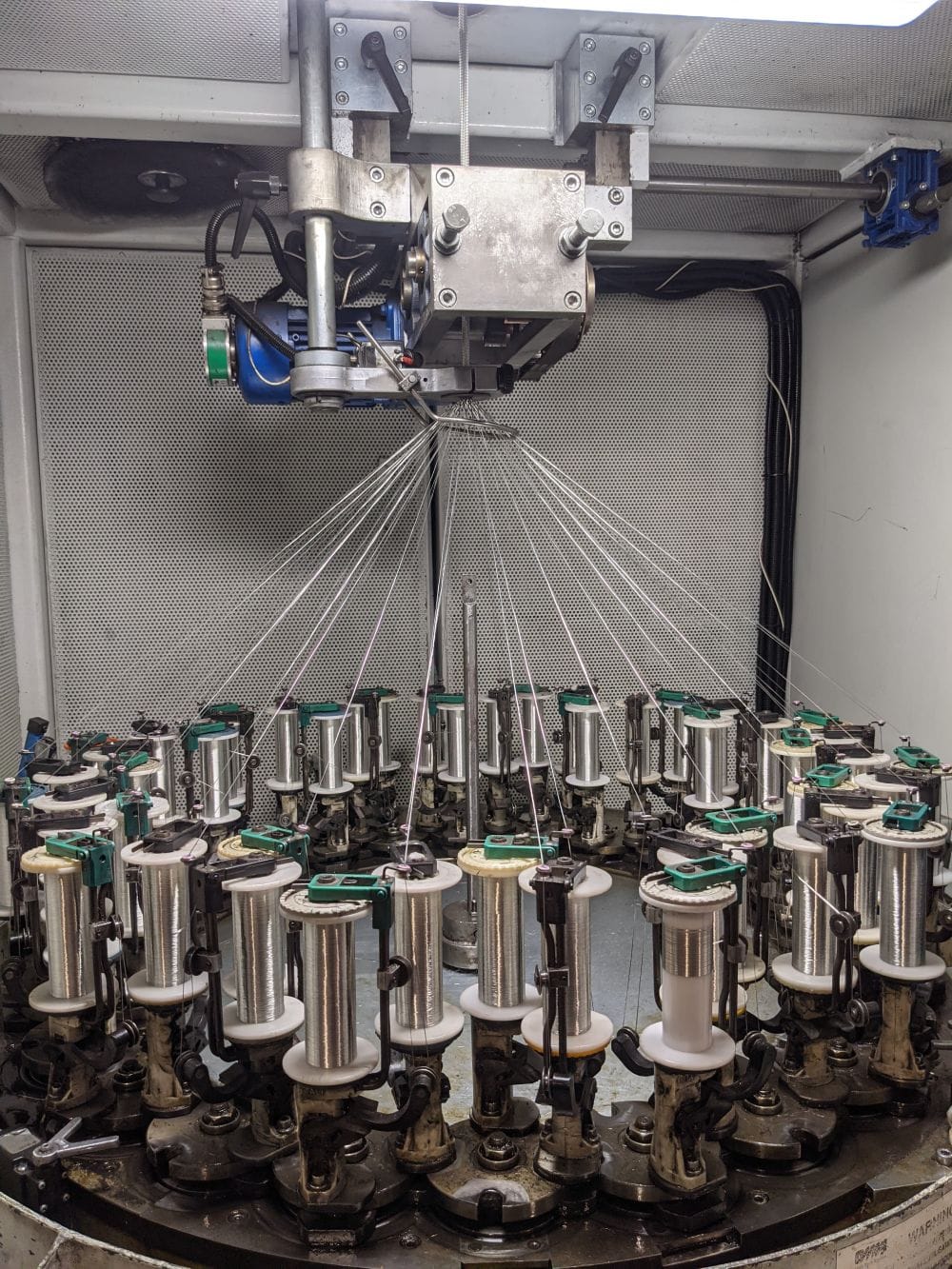

The braiding process interlaces multiple wire strands into a cylindrical configuration or a mesh, providing increased strength, flexibility, and shielding. Braided wire is widely used in demanding environments where abrasion resistance, electromagnetic interference (EMI) and radio frequency interference (RFI) protection are critical.

-

Cable Over-braiding

Over-braiding adds an extra layer of braided wire around existing cables for enhanced protection. This capability improves mechanical strength, abrasion resistance, EMI and RFI shielding, extending the lifespan of cables in harsh or high-performance environments such as aerospace, automotive, and industrial applications.

-

Custom Harness Braiding

Harness braiding involves creating customized braided coverings for wire harnesses. This operation caters to specific customer needs, offering tailored solutions for unique applications. It provides enhanced bundling, durability, and shielding, ensuring that wire harnesses perform reliably in complex and demanding systems.

Services We Offer

International Wire provides standard and custom wire products for a broad range of applications. Our wire products include copper single-end wire, stranded wire, braided wire, copper wire on bobbins, and flat wire.

The drawing process in wire manufacturing is a precise and critical operation that reduces the diameter of a copper rod to a finer gauge, while maintaining the material’s mechanical properties and surface finish. The drawing process is also the first process in cable manufacturing.

Stranding combines multiple individual wire strands to create a single, flexible conductor. This process enhances the wire’s durability and flexibility, making it suitable for dynamic applications such as power transmission, electronics, and automotive systems. Stranded wire is also less prone to fatigue compared to solid wire.

Wire bunching is the process of twisting together multiple single wire strands to form a flexible, compact conductor known as a bunched wire. Unlike stranded wire, where strands are precisely layered in a geometric pattern, bunched wire strands are randomly twisted, offering enhanced flexibility and ease of use in applications where movement, bending, or vibration is common. It is widely used in the manufacturing of cables for automotive, electronics, and consumer goods.

Wire is wound onto bobbins for easy handling, storage, and transportation. Bobbin winding supports production efficiency by delivering wire products in a ready-to-use format to our customers, who have their own braiding machines.

The braiding process interlaces multiple wire strands into a cylindrical configuration or a mesh, providing increased strength, flexibility, and shielding. Braided wire is widely used in demanding environments where abrasion resistance, electromagnetic interference (EMI) and radio frequency interference (RFI) protection are critical.

Over-braiding adds an extra layer of braided wire around existing cables for enhanced protection. This capability improves mechanical strength, abrasion resistance, EMI and RFI shielding, extending the lifespan of cables in harsh or high-performance environments such as aerospace, automotive, and industrial applications.

Harness braiding involves creating customized braided coverings for wire harnesses. This operation caters to specific customer needs, offering tailored solutions for unique applications. It provides enhanced bundling, durability, and shielding, ensuring that wire harnesses perform reliably in complex and demanding systems.

Products We Deliver

Bare and plated copper conductors

Bare and plated copper conductors

High-performance conductors from copper-based alloys and flat wire

High-performance conductors from copper-based alloys and flat wire

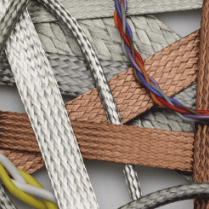

Flat and tubular wire braids made of copper, plated copper and stainless steel

Flat and tubular wire braids made of copper, plated copper and stainless steel

Bare and plated copper wire on bobbins for shielding

Bare and plated copper wire on bobbins for shielding

Various braided specialty textile products

Various braided specialty textile products

Our Business Units

Each business unit operated by International Wire offers specialty wire and engineered products to meet the most stringent requirements:

A leading manufacturer of bare and tin-plated copper wire conductors for a global customer base.

Specializes in high-performance conductors made of copper and copper alloys and plated with tin, nickel, or silver.

A manufacturer of braided wire products for military, commercial, and industrial applications.

A premier supplier of bus bar wires, braids, grounding wires, and more.

A designer and producer of copper strip- and braid-based flexible electrical connections.

Choose a Trusted Worldwide Partner in International Wire

With a history of innovation and expanded operations in Europe, International Wire is committed to satisfying customers based on our reputation for quality, reliability, and on-time delivery. Our goal is to make a positive impact for the benefit of all our stakeholders—our customers, employees, investors, and communities.

Contact us today to discuss your wire application, or request information about our products.