Grounding Strap: An Essential Component for Automotive Safety and Performance

The grounding strap is one of the most important parts of an electrical system. While many people overlook this integral component, it’s crucial for safety and performance in many industries, including automotive. Knowing more about how grounding straps function can help you select the right one for your specific application.

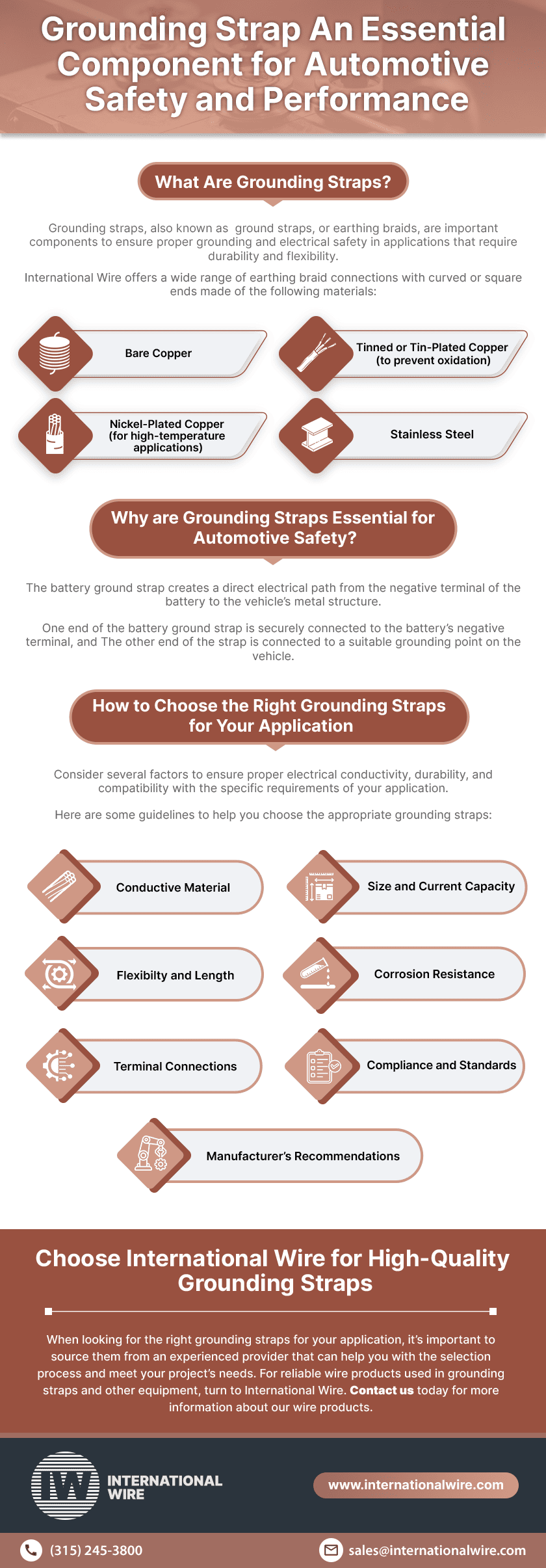

What Are Grounding Straps?

Grounding straps, or ground straps/earthing braids, are important components to ensure proper grounding and electrical safety in applications that require durability and flexibility. Grounding straps are more flexible than wire or busbars and provide connection of equipment in tight spaces. They are typically used in multiple industries as a direct electrical connection between different metal components or parts that may accumulate static charge or carry electrical current.

In the automotive industry, ground straps based on copper braids connect the vehicle’s battery negative terminal and the chassis or engine block. The primary purpose of the battery ground strap is to provide a low-resistance path for electrical current and establish a reliable ground reference for the vehicle’s electrical system. It allows for the safe dissipation of electrical charges and helps prevent electrical shock hazards.

Depending on the needs of the intended application, International Wire offers a wide range of earthing braid connections with curved or square ends made of the following materials:

- Bare Copper

- Tinned or tin-plated copper (to prevent oxidation)

- Nickel-plated copper (for high-temperature applications)

- Stainless steel

Our earthing braids are UL 467 certified (Standard for Grounding and Bonding Equipment). Those ground straps are designed from flat braids made of tinned copper wire to carry charge to ground.

Why Are Grounding Straps Essential for Automotive Safety?

The battery ground strap creates a direct electrical path from the negative terminal of the battery to the vehicle’s metal structure. This connection ensures that any fault currents or stray electrical charges are safely conducted to the ground, preventing damage to electrical components and minimizing the risk of electrical hazards.

One end of the battery ground strap is securely connected to the battery’s negative terminal, usually with a ring terminal that fits over the battery post and is fastened with a bolt. The other end of the strap is connected to a suitable grounding point on the vehicle, such as the engine block or chassis.

How to Choose the Right Grounding Straps for Your Application

When choosing the right grounding straps for your application, it’s important to consider several factors to ensure proper electrical conductivity, durability, and compatibility with the specific requirements of your application. Here are some guidelines to help you choose the appropriate grounding straps:

- Conductive material: select grounding straps made of high-conductivity materials, such as bare copper, tinned copper, or nickel-plated copper. These materials offer excellent electrical conductivity and are commonly used in automotive applications.

- Size and Current Capacity: Consider the size and current capacity required for your application. Larger vehicles or systems with higher current demands may require thicker or wider grounding straps to handle the electrical load effectively.

- Flexibility and Length: Evaluate the flexibility and length requirements based on the installation needs of your application. Grounding straps should be flexible enough to bend and route as needed without excessive strain. Ensure that the chosen length of the strap allows for proper connections between the components that need to be grounded.

- Corrosion Resistance: Automotive environments can be harsh, with exposure to moisture, chemicals, and temperature variations. Choose grounding straps that are resistant to corrosion and can withstand these conditions to ensure long-term reliability. Look for straps with appropriate coatings or materials, such as tinned copper or stainless steel, that offer corrosion resistance.

- Terminal Connections: Consider the type of terminal connections required for your application. Grounding straps usually come with ring terminals or lugs at each end for easy installation and secure connections. Ensure that the terminal connections are compatible with the battery terminals, grounding points, or other components you need to connect.

- Compliance and Standards: Verify that the grounding straps meet relevant industry standards to ensure quality and safety. Compliance with standards ensures that the grounding straps have undergone testing and meet specific performance criteria.

- Manufacturer’s Recommendations: Consult the recommendations provided by the manufacturer.

Choose International Wire for High-Quality Grounding Straps

When looking for the right grounding straps for your application, it’s important to source them from an experienced provider that can help you with the selection process and meet your project’s needs. For reliable wire products used in grounding straps and other equipment, turn to International Wire. Contact us today for more information about our wire products.

Shop our Grounding straps or contact us today for more information about our wire products.