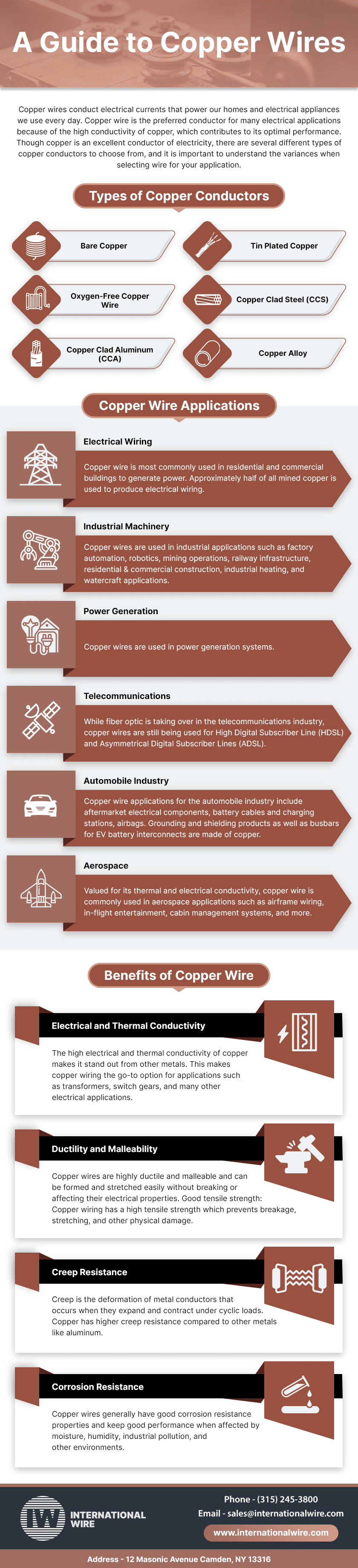

A Guide to Copper Wires

Copper wires conduct electrical currents that power our homes and electrical appliances we use every day. Copper wire is the preferred conductor for many electrical applications because of the high conductivity of copper, which contributes to its optimal performance. Suitable for a wide range of applications due to its versatility, copper requires less insulation and can be stretched more effectively than other metals. Though copper is an excellent conductor of electricity, there are several different types of copper conductors to choose from, and it is important to understand the variances when selecting wire for your application.

Types of Copper Conductors

Copper conductors are available in many different varieties, each with its own benefits. The types include:

- Copper Bare: As indicated by the name, bare copper does not have any coating. Bare copper wire has excellent conductive properties, high strength, good ductility, malleability, and creep resistance, making bare copper conductors ideal for applications in electrical transmission, jumpers, grounding electrical systems, electrical hookups, and electrical appliances.

- Copper Tin Plated: This is uninsulated copper wire coated with a thin layer of tin to protect against oxidation. A tin-plated copper wire has exceptional conductivity, weldability, and resistance to corrosive environments and is suitable for water treatment, desalination, power generation, and chemical processing applications.

- Copper Wire Plated with Nickel or Silver: This copper alloy conductor is often used in aerospace, defense, petrochemical, nuclear, and medical applications.

- Oxygen-Free Copper Wire: can be bare or plated. This is a top-grade type of copper wire that’s been refined in an electrically charged solution of copper sulfate and sulfuric acid, causing the copper to have an exceptionally low oxygen level (0.001%). Oxygen-free copper wire offers high thermal and electrical conductivity, great corrosion resistance and solderability, and higher temperature resistance, recrystallization, and workability making it suitable for applications that demand high durability and accuracy.

- Copper Clad Steel (CCS): This type of wire combines the high tensile strength of steel as its core and the conductive properties of copper as its outer layer. Common applications of copper-clad steel wire include temperature measuring instruments, medical products, motors, intelligent pressure, hardware, magnetic assemblies, and power supplies.

- Copper Clad Aluminum (CCA): With an aluminum core and an external layer of copper, copper-clad aluminum is a more affordable alternative to pure copper wire. CCA possesses increased strength compared to copper and enhanced conductivity compared to aluminum.

- Copper Alloy: Conductor made of copper alloy might include different chemical elements, which define the properties of the final product – copper alloy wire. Here are a few examples of copper alloys: Zirconium, Beryllium, Chromium, Cadmium, Brass and Bronze. Application and requirements for strength, solderability, durability, and insulation define which copper alloy conductor to utilize.

Copper Wire Applications

Copper wires are used in various applications:

- Electrical wiring: Copper wire is most commonly used in residential and commercial buildings to generate power. Approximately half of all mined copper is used to produce electrical wiring.

- Industrial machinery: Copper wires are used in industrial applications such as factory automation, robotics, mining operations, railway infrastructure, residential and commercial construction, industrial heating, and watercraft applications.

- Power generation: Copper wires are used in power generation systems as electrical conductors.

- Telecommunications: While fiber optic is taking over in the telecommunications industry, copper wires are still being used for High Digital Subscriber Line (HDSL) and Asymmetrical Digital Subscriber Lines (ADSL).

- Automobile industry: Copper wire applications for the automobile industry include aftermarket electrical components, battery cables and charging stations, shielding products, busbars for EV battery interconnects, and airbags.

- Aerospace: Valued for its thermal and electrical conductivity, copper wire is commonly used in aerospace applications such as airframe wiring, in-flight entertainment, cabin management systems, and more.

Benefits of Copper Wire

- Electrical and thermal conductivity: The high electrical and thermal conductivity of copper makes it stand out from other metals. This makes copper wiring the go-to option for applications such as transformers, switch gears, and many other electrical applications.

- Ductility and malleability: Copper wires are highly ductile and malleable and can be formed and stretched easily without breaking or affecting their electrical properties.

- Good tensile strength: Copper wiring has a high tensile strength which prevents breakage, stretching, and other physical damage.

- Creep resistance: Creep is the deformation of metal conductors that occurs when they expand and contract under cyclic loads. Copper has higher creep resistance compared to other metals like aluminum.

- Corrosion resistance: Copper wires generally have good corrosion resistance properties and keep good performance when affected by moisture, humidity, industrial pollution, and other environments.

Copper Wire Products at International Wire

Copper wiring is the most versatile wiring product with applications across industries. It offers excellent electrical and thermal conductivity, malleability and ductility, tensile strength, creep and corrosion resistance, as well as impressive alloy compatibility. At International Wire, we provide a wide range of copper wire products which include single-end wire and copper wire on bobbins, metal and textile braided products, stranded conductors, and flat wire. Contact us today to learn more, or request a quote.