Types of Copper Alloys

Unlike pure copper, copper alloys are complex formulations of metal with a copper base and alloy elements such as nickel, aluminum, silicon, tin, and zinc in varying concentrations that give the alloy desired properties. Learn more about popular copper alloys and their common applications.

ETP and OF Copper

Two popular alloys of copper are electrolytic tough pitch (ETP) copper and oxygen-free (OF) copper.

ETP Copper (C110)

For ETP copper properties, this alloy is extremely versatile and is the most commonly used copper alloy. It offers 100% IACS minimum conductivity, making it popular for electrical applications and those necessitating low resistance levels.

OF Copper (C101)

OF copper is a 99.99% pure copper alloy with 0.0005% oxygen content. This alloy has 101% IACS conductivity rating, it is resistant to oxidation, and less vulnerable to hydrogen embrittlement.

Properties

Both ETP and OF coppers are malleable, making them easy to work with and form during manufacturing. These alloys offer high levels of thermal and electrical conductivity and low chemical reactivity. They also have resistance properties for oxidation, corrosion, microbes, and bacterial contamination.

Applications

Some of their most common applications include:

- Aerospace parts

- Construction

- Electronics

- Elements in heat exchangers

- Medical equipment

- Power transmission lines and components

Cadmium Copper (C162)

Cadmium copper is a high-performance alloy made from 98 – 99 % % copper, 0.1 – 1.5% cadmium and sometimes minor amounts of other materials. The cadmium imbues the metal with more strength and makes it responsive to some heat treatments.

Properties

Cadmium copper offers an extended flex life and good tensile strength characteristics, making it a more pliable option for industrial and scientific applications. The alloy also has excellent thermal stability and a high degree of electrical conductivity.

Applications

Some of the most popular applications of cadmium copper include:

- Electrical components (circuit breaker switches, connectors, spring contacts, electrical conductors)

- Trolley wire

- Geophysical exploration equipment

- High strength transmissions lines

Tensile-Flex High-Performance Copper Alloy

This alloy is recognized as a high-performance conductor alloy that can perform specialized functions while meeting or exceeding the requirements of industrial regulations. Tensile-flex high-performance copper alloy complies with the following industrial standards:

- ASTM B624

- MIL-W-29606

- NEMA WC67

- SAE AS22759

Properties

This alloy has high tensile strength and maintains this key characteristic even at elevated temperatures of 700° F and higher. The material also has high thermal stability and excellent conductivity characteristics and can resist annealing at high temperatures.

Applications

Because this alloy retains its positive characteristics at high temperatures, it’s an excellent choice for:

- Aerospace

- Medical applications

- Geophysical applications

80EF: Environmentally Friendly Copper Alloy

80EF copper is a Restriction of Hazardous Substances (RoHS)-compliant alternative to cadmium copper. This alloy doesn’t have cadmium and other heavy metals like lead or mercury in its composition.

Properties

Despite not having cadmium, 80EF still has extremely favorable characteristics, such as good flex life and tensile strength, and it operates similarly to cadmium copper. It’s also highly conductive and offers good thermal stability.

Applications

This alloy is ideal for applications that must comply with RoHS regulations and requirements. Additional applications include:

- Commercial aerospace applications

- Geophysical exploration components

- Medical equipment

35EF: Environmentally Friendly Copper Alloy

35EF copper alloy is free of heavy metals like cadmium, lead, or mercury. Alloy 35EF copper also complies with several specialized industry standards, including:

- ASTM B624

- MIL-W-29606

- NEMA WC67

- SAE AS22759

Properties

35EF is thermally stable and offers excellent conductivity. It also has a high tensile strength that makes it ideal for a variety of applications.

Applications

This alloy is a popular choice for any RoHS application due to its directive compliance.

CS-95: Ultra-High Strength Copper Alloy

This alloy has a composition that offers increased strength for use in extreme environments. It allows manufacturers to decrease the size and weight of components without sacrificing strength or integrity.

Properties

Ultra-high-strength copper alloy has excellent strength- and conductivity-to-weight ratios as well as a high degree of tensile strength. This durable alloy has excellent flex life in mechanical applications, and it’s another RoHS-compliant alloy.

Applications

Components fabricated from ultra-high strength copper alloy CS-95 are used in the following applications:

- Aerospace and aeronautic cabling systems

- Miniature electronics

- Medical diagnostic equipment

- Miniature Invasive Medical Sensors and Probes

Bronze

Bronze alloys are composed primarily of copper and about 12-12.5% tin, as well as other metals, such as aluminum, manganese, nickel, phosphorus, or silicon.

Properties

Regarding bronze’s properties, the alloy is well regarded for its strength, resistance to corrosion and conductivity.

Applications

Some of the most common applications of bronze include:

- Automotive parts

- Electronic and electrical components, including contacts and relays

- Marine components

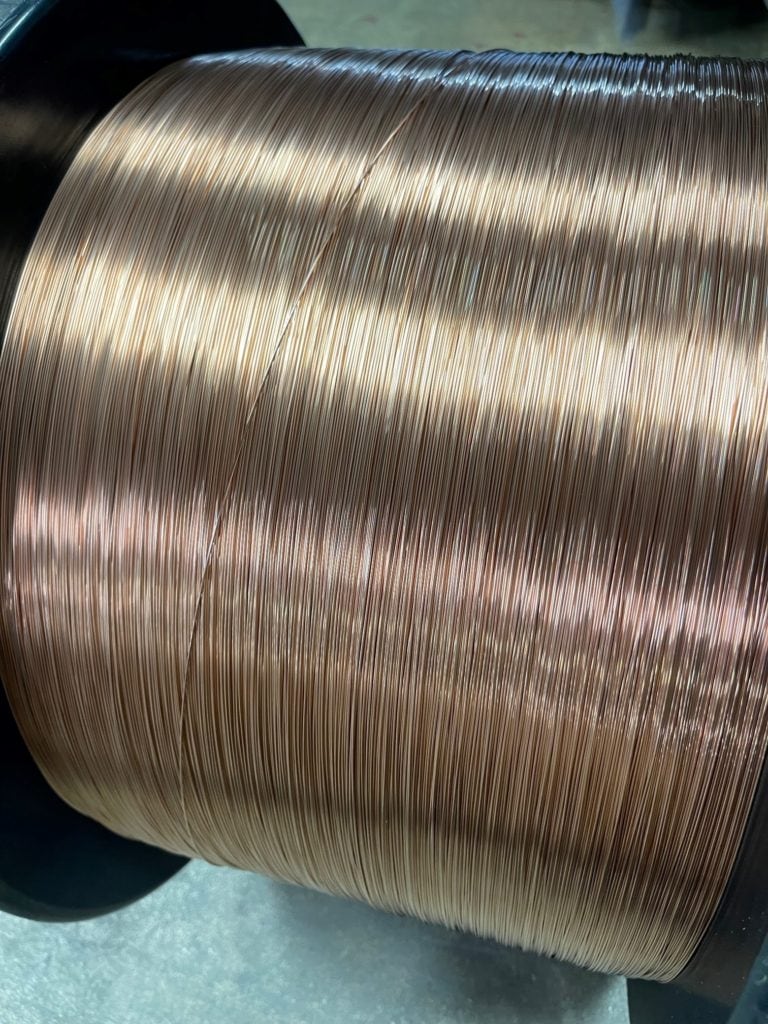

Copper Alloy Wires at International Wire

As a leading U.S. manufacturer of copper alloy wire products, International Wire Group utilizes high-quality metals to meet clients’ unique specifications. Contact us today to learn more about our selection of copper alloys or our in-house cable services.