Electric vehicles (EVs) rely on wiring and busbars to carry high-voltage currents to the battery from external charging units. Wiring and busbars also deliver electricity from the battery to the components and systems of the electric vehicle. They are vital components, contributing to the vehicle’s performance and safety. International Wire manufactures and supplies high-quality conductors for EV wiring and cables, and busbars.

EV cables

There are two main types of electric vehicle cables:

- EV Battery Cables are responsible for transmitting power between the battery pack and various electric systems. Unlike low-voltage ICE cables, battery cable for EVs and Hybrid vehicles are designed for higher electrical currents and voltage and operate at voltages ranging from a few hundred volts to over 1,000 volts.

- EV Charging Cables are used for connecting the vehicle to an outside electrical source.

EV Battery Cables typically feature bare copper or tinned copper bunched or rope-bunched conductors of large gauges with high strand count.

Electric vehicles (EVs) are typically equipped with two different charging cables. A Type 1 charging cable is used for recharging in a three-pin socket. The Type 2 EV charging cable is used at many public charging stations and home EVSEs (EV charging stations). Popular models of EVs include the Nissan Leaf, Tesla Model S, and the BMW i3.

EV Charging Cables typically feature several bare copper bunched conductors of various sizes.

Other EV charging cables and components might include:

- THHN Building wire and data cables to connect the grid to the charging station.

- Charging station switchboard wire, data cables, and switch boxes.

- Connectors, cord grips, and receptacles for connecting the charging station to the vehicle.

- Primary automotive wire.

- Standard battery cable, used in PHEVs.

- Ethernet cables, ISO wire, and CAN bus cable.

International Wire offers conductors in variety of sizes and constructions for EV Battery Cables and Charging Stations.

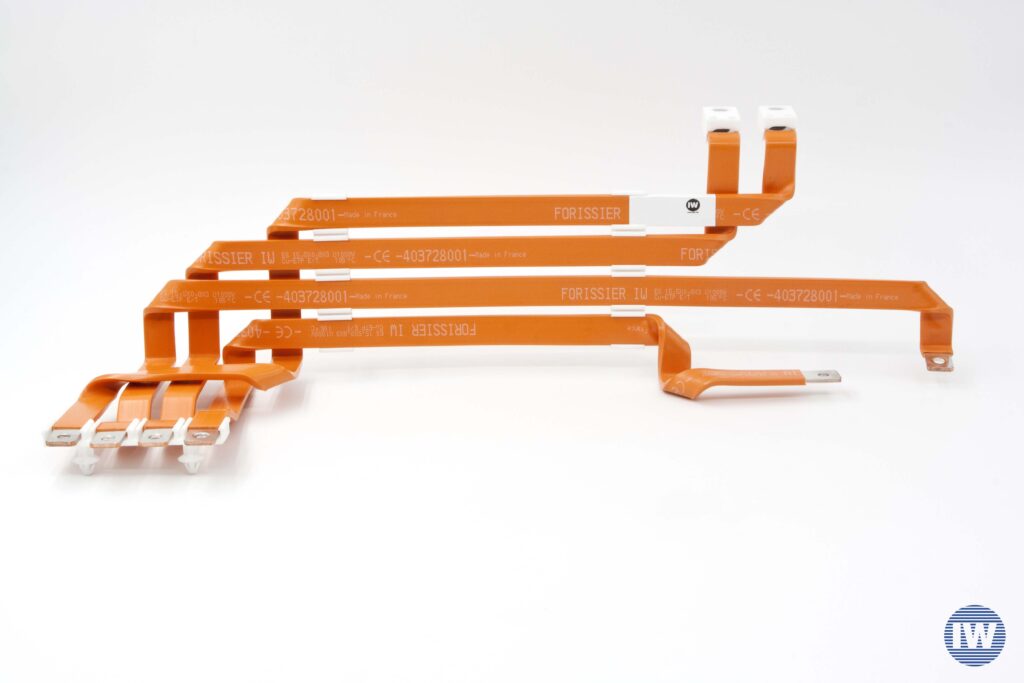

EV Busbars

EV busbars are usually laminated flat bars, which are made of copper or aluminum. Busbars are critical to the operation of EVs, offering electric current power distribution from the EV batteries to powertrain and numerous electrical components in the vehicle.

Busbars have several advantages over cables. Busbars carry more current than cables with the same cross-sectional area. OEMs aim to increase power to EVs’ batteries to reduce charging time, and a busbar can support up to 15 percent more power than a cable with the same cross-sectional area. In addition, busbars influence the thermal management of the EV: the larger surface area of a busbar dissipates heat more efficiently than a cable over its entire length, this is another advantage as OEMs seek to increase power levels.

Laminated and flexible busbars find common use in EVs:

Laminated busbars are produced from the assembly of multiple layers of conductive copper strips. Copper strips are separated by thin layers of dielectric material. Heating is applied to these layers to form a rigid, integrated component.

Flexible busbars are also made from layers of copper strip which are tightly attached to mounting areas. The ends of a flexible busbar are rigid to ensure a secure connection but have a flexible center.

The main similarity between laminated busbars and flexible busbars is that they are both multi-layered. However, the difference is that laminated busbars are sturdy and rigid structures, while the same cannot be said about flexible busbars.

Benefits of Using EV Busbars

Busbars function as electric current distribution system from the batteries to the vehicle’s components and systems. They are the primary conductor for the vehicle and offer thermal management that is vital to EV operation. Busbars have a unique design that offers the following benefits to EVs:

- Lower manufacturing costs and decreased assembly time, inventory requirements, and internal material handling.

- They are more flexible, allowing manufacturers to customize the busbars for optimal reliability and efficiency.

- The busbars reduce wiring errors and are highly recommended for increased reliability, enhanced electrical performance, and reduced maintenance and service costs.

Conductors for EV Wiring and Busbars From International Wire

Conductors for EV wiring, battery charging cables, and flexible busbars from International Wire deliver a high-performance solution for EVs.

International Wire offers various copper conductor constructions to serve in critical applications, such as automotive, industrial, aerospace, and medical sectors. Our quality assurance and customer service have earned us a reputation for excellence in the United States and Europe. Contact us or request a quote to speak with a team member about our EV wiring and busbar solutions.